ATEX CERTIFIED PRODUCTS FOR EX ZONES

ATEX CERTIFICATION

ATEX Certification: The Key to Choosing Reliable and Safe ATEX certified Products

Costs of disastrous accidents, fire and explostions or short circuits during floods in industrial zones like mining, gas, oil chemical and pharmaceutical industries can be staggering. In order to minimize risks and costs it’s worth for all campanies to invest in best secure specially designed and tested equipment labeled as ATEX certfied.

The ATEX certification is a prove of reliability and safty of various equipment, ensuring compliance with strict standards. The most important aspect of the ATEX ratings is the classification of hazardous areas into different zones. These EX zones are ranked based on the probablity of occurance and duration of an explosive atmosphere.

A comprehensive and professional ATEX certification service offered by PE PROJECT can help achieve the necessary results.

Understanding the importance of ATEX certification of all equpipment in EX zones is crucial for ensuring safety in potentially explosive atmospheres. ATEX is derived from french and stands for “Atmosphères Explosibles,” which translates to “Explosive Atmospheres.” This certification proves that certified products are designed, manufactured, and tested in accordance with all required ATEX regulations for safe application in dengerous environments called EX zones.

EX zones or ATEX zones are areas where there is a potential risk of short circuit, sparks, explosion due to potential presence of flammable gases, vapors, or dust. Those zones are ordered based on the likelihood and frequency of explosive atmospheres.

EX zones classification:

Zone 0: This is the most hazardous zone, where an explosive atmosphere is present continuously or for long periods. Example: Inside a tank or container where flammable gas (hydrogen, methane, syngas etc.) or liquids (crude oil, petrol etc like are stored.

Zone 1: An explosive atmosphere may occasionally develop during normal operations. For instance, this can happen in areas surrounding the openings of tanks or containers that hold flammable liquids.

Zone 2: An explosive atmosphere is not expected during normal operations, but if it does occur, it will only last for a short time. Example: Areas where flammable liquids are handled but are typically contained.

Zone 20: This zone is akin to Zone 0 but specifically pertains to dust. An explosive atmosphere in the form of a combustible dust cloud is present continuously or for extended periods. Example: Inside silos or containers where combustible dust is stored.

Zone 21: An explosive atmosphere in the form of a combustible dust cloud may occur occasionally during normal operations. Example: Areas surrounding machinery that processes combustible dust.

Zone 22: An explosive atmosphere in the form of a combustible dust cloud is not expected during normal operations, but if it does occur, it will only last for a short time. Example: Areas where combustible dust is handled but are usually contained.

What is ATEX Certification Process

ATEX certification is a process that includes several stages:

Product Evaluation: the product is evaluated by a notified body, which is an independent organization designated by the government. The notified body (such as TUV, IMQ, CESI, and others) evaluates the product’s design, construction, and performance to ensure it meets the necessary safety requirements.

Type Examination: The notified body conducts tests on a sample of the product to confirm its compliance with the standards and directives. This includes evaluating its resistance to ignition sources, short circuits and other sources of sparks its ability to prevent explosions, and its overall safety features.

Quality Assurance: The manufacturer must implement a quality management system to ensure constant compliance with ATEX requirements. This involves documenting procedures, performing regular audits, and maintaining product traceability.

Issuance of Certificate

A product that has successfully passed all necessary assessments is labeled as ATEX rated and awarded an ATEX certificate. This certificate is proof that the product meets the safety standards required in potentially explosive environments. The ATEX approval is issued for a specified period and requires renewal.

ATEX Certification Requirements and Standards

ATEX certification is regulated by two European Union directives: ATEX Directive 2014/34/EU (ATEX 114) and ATEX Directive 1999/92/EC (ATEX 153). These directives legally regulate the manufacturing and application of equipment in EX zones. ATEX 114 directive describes the requirements for manufacturers, while ATEX 153 describes on the responsibilities of employers to protect workers in EX zones. All these directives provide a approach to ensuring safety in hazardous areas.

The requirements for ATEX certification:

Design and Construction: Products must be designed and built to reduce the risk of ignition, which includes protection against static electricity, electrical sparks, short circuits and hot surfaces. They should also incorporate suitable sealing and containment measures to prevent the escape of flammable substances.

Marking and Labeling: Products that are ATEX-certified must display the “Ex” mark, indicating compliance with the ATEX directives. This label is accompanied by a code that details the product category and the type of protection it offers. Documentation and Traceability: Manufacturers are obligated to provide documentation, including technical files, user manuals, and test reports, to prove compliance with ATEX standards. This documentation is essential for ensuring traceability and facilitating proper maintenance and repair of the equipment.

Training and Competence: Employers must provide proper training for workers that will be responsible for handling equipment in explosive atmospheres.

This includes educating personnel about the risks, safety procedures, and the correct use of ATEX-certified equipment. By following these requirements and standards, ATEX certified products offer a greater level of safety and reliability compared to non-certified options.

Benefits of Using ATEX Certified Products

Implementing and utilizing ATEX certified products presents several advantages, both in terms of

safety and operational efficiency. Some key benefits include:

1. Enhanced Safety: ATEX-certified products have been rigorously tested to ensure they resist ignition sources and prevent explosions. Thanks to these products, businesses can significantly lower the risk of accidents, explosions, injuries, and expensive damage caused by explosions.

2. Compliance with Regulations: Many countries have made ATEX certification a legal requirement for equipment used in EX zones. By choosing ATEX certified products, businesses can ensure they meet these regulations and avoid penalties or legal issues.

3. Improved Reliability: ATEX rated products are designed and manufactured to comply with strict quality standards. They undergo comprehensive testing to confirm their performance in hazardous environments, providing businesses with dependable equipment that can endure the challenges of ATEX zones.

4. Long-Term Cost Savings: Although ATEX certified products may come with a higher initial price compared to non-certified alternatives, they yield long-term cost savings. By preventing accidents and equipment failures, businesses can avoid costly downtime, repairs, and potential legal liabilities. It is crucial for decidents to weigh these benefits when choosing equipment for hazardous environments. Focusing on safety and investing in ATEX-certified products can greatly enhance both the financial performance and the well-being of employees.

Despite the significance of ATEX certification, there are several common misconceptions that can create confusion or misinterpretation.

Let’s clarify a few of these misunderstandings: ATEX certification is only applicable to explosive gases: Although ATEX is frequently linked to explosive gases, it also encompasses other hazardous materials, including flammable dust and combustible fibers. The certification ensures that products can be safely utilized in any potentially explosive atmosphere, regardless of the specific substance involved. ATEX-certified products are always pricier: While it’s true that ATEX-certified products may come with a higher upfront cost, the long-term advantages often justify the expense. Enhanced safety, reliability, and adherence to regulations can result in cost savings through fewer accidents, reduced downtime, and lower legal liabilities. ATEX certification guarantees complete safety: The ATEX certification process is thorough and significantly lowers the risk of accidents and explosions. However, it does not completely eliminate all risks. It’s crucial for businesses to continue following proper safety protocols and maintain ATEX-certified equipment to ensure maximum safety. Recognizing these misconceptions can assist businesses in making informed choices when selecting ATEX-certified products. How to Choose Reliable and Safe ATEX Certified Products Selecting dependable and safe ATEX rated products necessitates careful thought and attention to detail. Here are some important factors to keep in mind when choosing equipment for hazardous environments:

Identify Your Specific Requirements: Analyze your work environment to pinpoint the specific hazards and risks involved. Take into account the types of explosive substances, the temperature range, and other critical factors. This assessment will help you determine the appropriate level of protection needed for the equipment.

Verify ATEX Certification: Make sure that the product you are considering has a valid ATEX certification. Confirm the certification with the issuing body or check their online database. This step is essential to ensure that the product complies with the necessary safety standards. Evaluate Manufacturer Reputation: Investigate the manufacturer’s reputation and history in producing ATEX-certified products. Look for companies that demonstrate a strong commitment to safety, quality, and compliance. Customer reviews, industry certifications, and case studies can offer valuable insights.

Consider Product Features: Examine the specific safety features and design elements of the product. Look for attributes such as explosion-proof enclosures, durable seals, effective grounding mechanisms, or anti-static properties. These features can enhance safety and reduce the risk of ignition sources. Seek Expert Advice: Consult with experts or connect with reputable suppliers who specialize in ATEX rated products. They can offer valuable guidance and assist you in navigating the complexities of selecting the right equipment for your specific needs. By following these steps, businesses can make informed decisions and choose reliable and safe ATEX-certified products that cater to their unique requirements.

Here are some examples that illustrate the positive effects of ATEX certification:

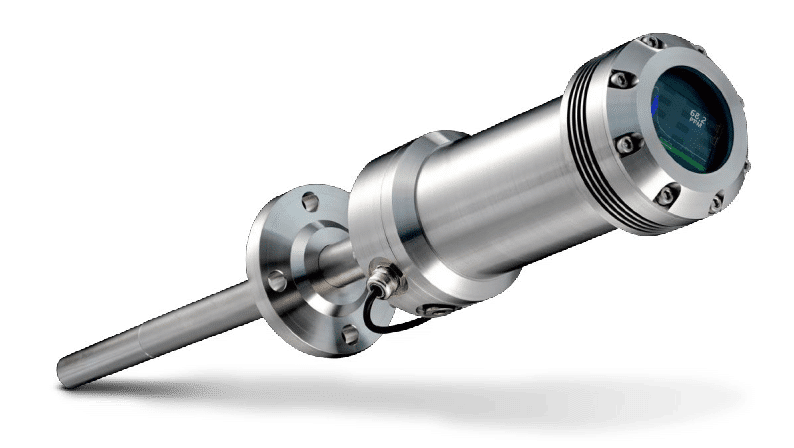

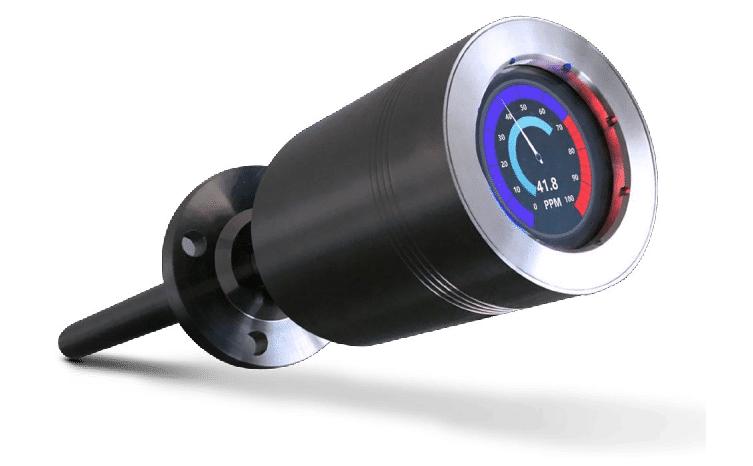

gas and oil atex products

Oil and Gas Industry: In oil refineries, offshore platforms, and petrochemical plants where flammable gases and vapors are common, ATEX-certified equipment is crucial. It ensures personnel safety, prevents explosions, and reduces the likelihood of severe accidents. An offshore oil platform adopted EX Zones certified electrical equipment, including lighting fixtures and control panels. This led to enhanced safety, decreased downtime from equipment failures, and adherence to regulations.

RECOMMENDATED ATEX RATED products for gas and oil industry

Chemical Processing Industry: Chemical plants often handle hazardous materials that can create explosive environments. Intrinsically safe equipment, such as pumps, mixers, and valves, is essential for preventing accidents and ensuring operational safety.

Pharmaceutical Industry: The manufacturing of pharmaceuticals involves working with flammable substances, solvents, and dust. ATEX-certified equipment and facilities help reduce the risks associated with these materials, ensuring both worker safety and product quality. A pharmaceutical manufacturing facility upgraded to ATEX rated machinery and equipment, which not only improved safety and lowered the risk of explosions but also boosted production efficiency and quality control.

Mining Industry: Mines are naturally susceptible to explosive atmospheres due to flammable gases and dust. ATEX-certified mining equipment, including electrical systems, ventilation, and machinery, plays a vital role in protecting miners and preventing accidents. A mining company implemented new intrinsically safe mining machinery, such as explosion-proof drills and ventilation systems. This resulted in a safer work environment, increased productivity, and compliance with safety regulations.

Food and Beverage Industry: Certain operations in food processing and beverage production can involve substances that create explosive atmospheres. Using ATEX-rated equipment, like mixers, dryers, or packaging machinery, helps ensure worker safety and reduces the risk of explosions. ATEX certification provides a consistent safety standard across these industries, protecting workers, assets, and the environment. These case studies highlight the real benefits businesses can gain by investing in ATEX-rated products.

Conclusion: Making Informed Decisions with ATEX Certification In hazardous environments, prioritizing safety is crucial. ATEX certification provides a dependable and standardized framework for selecting equipment that can be safely used in potentially explosive atmospheres. When choosing ATEX-rated products, it’s important to consider specific requirements, verify the certification, assess the manufacturer’s reputation, and seek expert advice. By following these steps, businesses can confidently choose reliable and safe equipment that meets the necessary compliance standards.

When choosing the right company that will guide succesfuly through the ATEX certification process it’s worth to cooperate with a serious and reliable partner like PE PROJECT.